Capacities

Milling - CNC

Toyoda

FV 1680 Vertical Machining Centre. 50 taper, 20 station tool changer with 63” x 31.5” x 31.5” travel. Rotary 4th axis.

Toyoda

Stealth 1365 Machining Center. 40 taper, 24 station tool changer with 63” x 31.5” x 31.5” of travel.

Matsura

Maxia MX520 5 axis Vertical Machining Center. 40 Taper, 60 station tool changer with 24.8″ x 22.04″ x 20.07″ of travel.

Horizontal Boring Mill

50 taper, Heidenhain TNC 410 CA controller. 4th axis 48″ table with 63.37” x 48.75” x 48” travel

Leadwell

1300 Vertical Machining Centre. 50 taper, 20 station tool changer with 52” x 30” x 30” travel.

OKK

VM5 II Vertical Machining Centre. 50 taper, 20 station tool changer with 40” x 20” x 20” travel.

Trak DPM

Power Drawbar, 30” x 17” x 18” Travel.

Trak FHM7

Power Drawbar, 60″ x 23″ x 20.5″ travel.

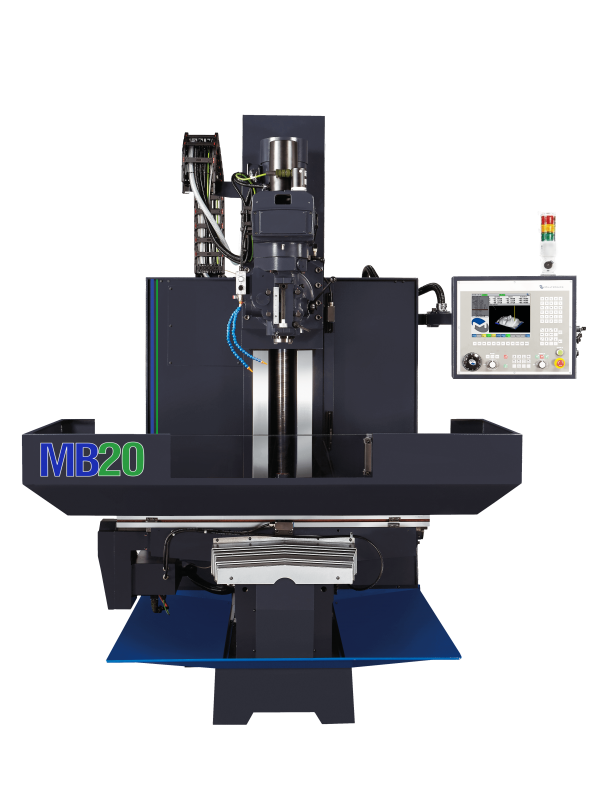

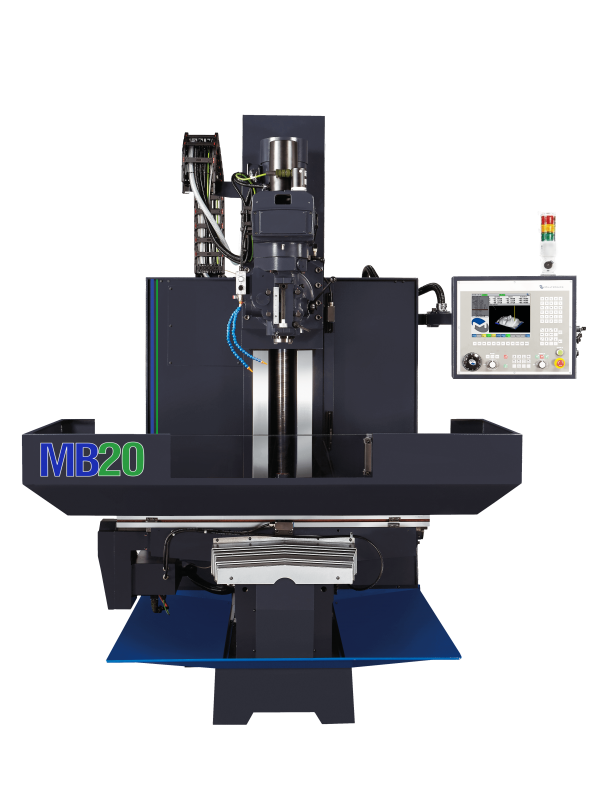

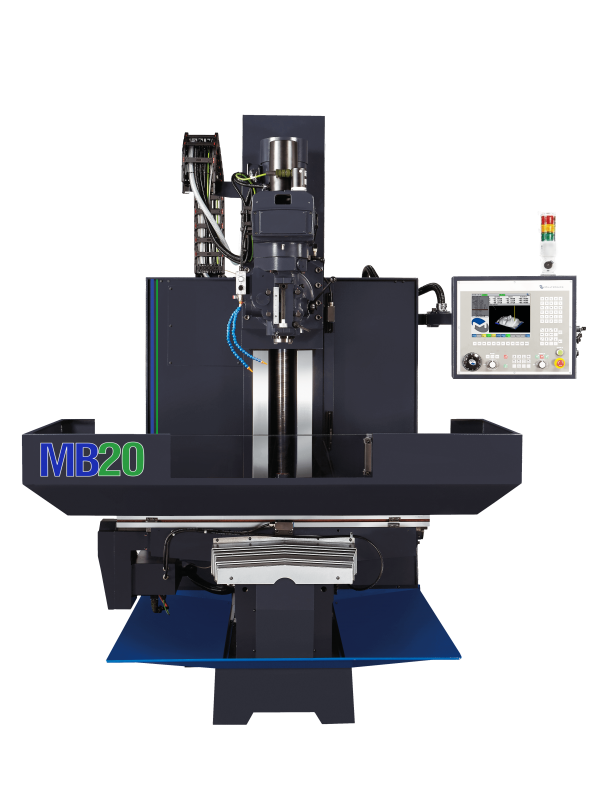

Milltronics

MB 20, Power Drawbar, 40” x 20” x 24” travel.

Milling - Manual

Fortworth Vertical Mill

50 taper, c/w 3-Axis Readout, with 60” x 24.25” x 25.75” travel

Dah-Lih Universal Mill

Acu-Rite III, 3 Axis with 38”x 14”x 17” power travel

First Knee mills

Heidenhain DRO up to 31”x 15.5”x 22” travel, 5” spindle

2 machines in total

Lathes - CNC

Mori Seiki

Model SL-400 BMC/2000 CNC Lathe, 25.5” swing x 81.2” between centres, 50 H.P. spindle motor, 18” chuck and 12 H.P. at the 12 station live tooling.

Nakamura- Tome

SC-250 CNC Lathe 8″ swing x 27″ between centres

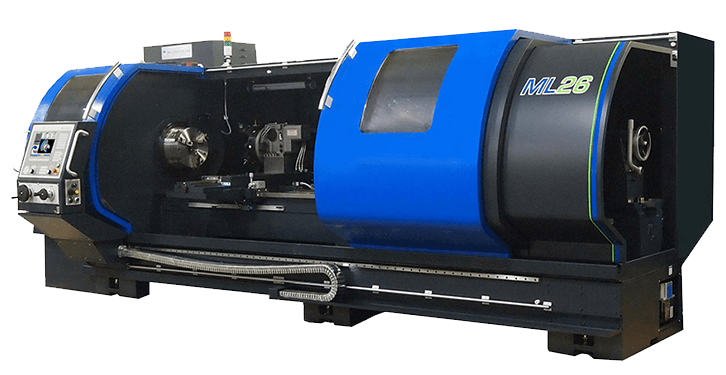

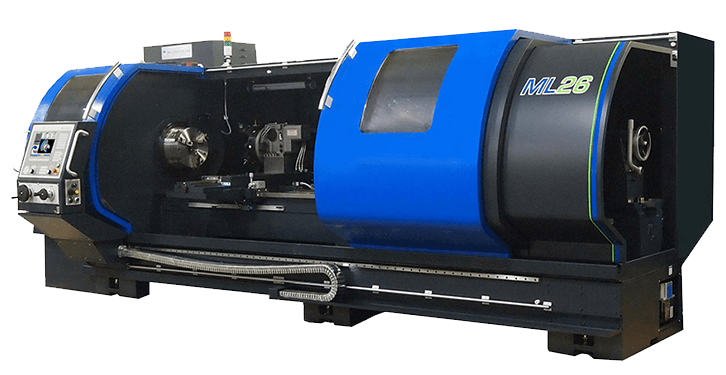

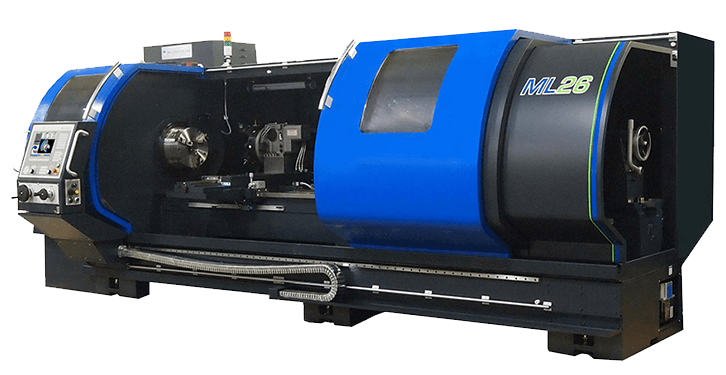

Milltronics

ML 26 CNC lathe with 160” length, and 27” swing . 8 station turret.

SNK

SUT-12/2000 CNC Lathe, 6.5” swing x 33.2” between centres.

Lathes - Manual

TOS

Model SU 90 over the carriage, 46” maximum turning diameter, 264” between centers.

Stanko

Model 16K25-19.5” swing and 59” between centers.

Stanko

1I611P Lathe, with 10” swing and 24” between centers.

Grinding

Surface Grinders

All Tool has a total of 4 surface grinders.Our largest Chevalier Surface Grinder is equiped with a 11.75” x 23.5” chuck and has 26” x 13” x 14” travel with coolant and auto traverse

Heinman Tool & Cutter Grinder

In addition we have a diamond wheel tool and cutter grinder made by Heinman that is fitted with a compound rotary collet,

giving us the ability to create and manfuacture our on custom cutters when needed.

EDM

EDM Technology

a manufacturing process whereby a wanted shape of an object is obtained using electrical discharges (sparks). The material removal from the workpiece occurs by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. The collateral effect is that the material is broken down and carried away by the liquid.

Very tight tollerances and super finishes can be obtained by this process with adjustments to voltage / amperage and number of passes.

Wire EDM

This machine gives us exacting wire cutting abilities with full 4 axis ablities. This allows for precision features and complicated extrusion dies. (2 Machines total)

Part sizes up to 36″‘x24″19.9″

Sinker EDM

Die sinking EDM allows us to insert complex pockets and shapes into materials that may not be possible by any other method.

Part sizes up to 36″x24″x10″

Portable Machining

Line Boring and Hole Repair

- 1-1/4″ OD x 68″ long boring bar (machine faces from 1-1/2″ to 6″)

- 2-1/2″ OD x 96″ long boring bar (machine faces from 2-1/2″ to 18″)

With these two bars, holes from 1-1/2″ to 18″ can be bored. With some tool modifications holes smaller and larger (up to 24″) can be bored. Both bars are hydraulically driven (600 or 220 volt 3 diameter).

Bore repair is offered in 3 options:

- Bore and Bush

- Bore, customer welds and rebore to size

- With advanced notice of 36 to 48 hours we will bore, weld and bore to size

Blind Hole Boring and Repair

- 2-1/4″ OD bar

- hydraulic driven (600 or 220 vault 3 phase)

- Same 3 options of hole repair apply to this unit

- With advanced notice, this unit can be driven with 110 vault electric or pneumatic

Shaft Repair

- 18″ lathe bed with 12″ of automatic feed on “X” and 4″ of manual feed on “Y” axis.

- 36″ lathe bed wiqh 30″ of automatic feed on “X” and 4″ of manual feed on “Y” axis

Lathes can be mounted parallel to turning shafts. They are rotated by their own power or can be rotated by a portable means. Lathes can be placed anywhere along length of shafts. Can also be mounted perpendicular to shafts for thrust machining.

Options for shaft repair:

- We machine, sleeve and remachine to size

- We machine, customer welds and machines to size

Flange Facing + Drilling & Tapping

available with advance notice

CMM

LK Metrology

LK G80C Coordinate Measuring Machine. Travel distances: X: 2,500 mm (100 in), Y: 1,500 mm (60 in), Z: 1,000 mm (40 in). Powered by Polyworks software.

Milling - CNC

Toyoda

FV 1680 Vertical Machining Centre. 50 taper, 20 station tool changer with 63” x 31.5” x 31.5” travel. Rotary 4th axis.

Toyoda

Stealth 1365 Machining Center. 40 taper, 24 station tool changer with 63” x 31.5” x 31.5” of travel.

Matsura

Maxia MX520 5 axis Vertical Machining Center. 40 Taper, 60 station tool changer with 24.8″ x 22.04″ x 20.07″ of travel.

Horizontal Boring Mill

50 taper, Heidenhain TNC 410 CA controller. 4th axis 48″ table with 63.37” x 48.75” x 48” travel

Leadwell

1300 Vertical Machining Centre. 50 taper, 20 station tool changer with 52” x 30” x 30” travel.

OKK

VM5 II Vertical Machining Centre. 50 taper, 20 station tool changer with 40” x 20” x 20” travel.

Trak DPM

Power Drawbar, 30” x 17” x 18” Travel.

Trak FHM7

Power Drawbar, 60″ x 23″ x 20.5″ travel.

Milltronics

MB 20, Power Drawbar, 40” x 20” x 24” travel.

Milling - Manual

Fortworth Vertical Mill

50 taper, c/w 3-Axis Readout, with 60” x 24.25” x 25.75” travel

Dah-Lih Universal Mill

Acu-Rite III, 3 Axis with 38”x 14”x 17” power travel

First Knee mills

Heidenhain DRO up to 31”x 15.5”x 22” travel, 5” spindle

2 machines in total

Lathes - Manual

TOS

Model SU 90 over the carriage, 36” swing over the bed, 264” between centers.

Stanko

Model 16K25-19.5” swing and 59” between centers.

Stanko

1I611P Lathe, with 10” swing and 24” between centers.

Lathes - CNC

Mori Seiki

Model SL-400 BMC/2000 CNC Lathe, 25.5” swing x 81.2” between centres, 50 H.P. spindle motor, 18” chuck and 12 H.P. at the 12 station live tooling.

Nakamura- Tome

SC-250 CNC Lathe 8″ swing x 27″ between centres

Milltronics

ML 26 CNC lathe with 160” length, and 27” swing . 8 station turret.

SNK

SUT-12/2000 CNC Lathe, 6.5” swing x 33.2” between centres.

Grinding

Surface Grinders

All Tool has a total of 4 surface grinders.Our largest Chevalier Surface Grinder is equiped with a 11.75” x 23.5” chuck and has 26” x 13” x 14” travel with coolant and auto traverse

Heinman Tool & Cutter Grinder

In addition we have a diamond wheel tool and cutter grinder made by Heinman that is fitted with a compound rotary collet,

giving us the ability to create and manfuacture our on custom cutters when needed.

EDM

EDM Technology

a manufacturing process whereby a wanted shape of an object is obtained using electrical discharges (sparks). The material removal from the workpiece occurs by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. The collateral effect is that the material is broken down and carried away by the liquid.

Very tight tollerances and super finishes can be obtained by this process with adjustments to voltage / amperage and number of passes.

Wire EDM

This machine gives us exacting wire cutting abilities with full 4 axis ablities. This allows for precision features and complicated extrusion dies.(2 Machines total)

Part sizes up to 36″‘x24″19.9″

Sinker EDM

Die sinking EDM allows us to insert complex pockets and shapes into materials that may not be possible by any other method.

Part sizes up to 36″x24″x10″

Portable Machining

Line Boring and Hole Repair

- 1-1/4″ OD x 68″ long boring bar (machine faces from 1-1/2″ to 6″)

- 2-1/2″ OD x 96″ long boring bar (machine faces from 2-1/2″ to 18″)

With these two bars, holes from 1-1/2″ to 18″ can be bored. With some tool modifications holes smaller and larger (up to 24″) can be bored. Both bars are hydraulically driven (600 or 220 volt 3 diameter).

Bore repair is offered in 3 options:

- Bore and Bush

- Bore, customer welds and rebore to size

- With advanced notice of 36 to 48 hours we will bore, weld and bore to size

Blind Hole Boring and Repair

- 2-1/4″ OD bar

- hydraulic driven (600 or 220 vault 3 phase)

- Same 3 options of hole repair apply to this unit

- With advanced notice, this unit can be driven with 110 vault electric or pneumatic

Shaft Repair

- 18″ lathe bed with 12″ of automatic feed on “X” and 4″ of manual feed on “Y” axis.

- 36″ lathe bed wiqh 30″ of automatic feed on “X” and 4″ of manual feed on “Y” axis

Lathes can be mounted parallel to turning shafts. They are rotated by their own power or can be rotated by a portable means. Lathes can be placed anywhere along length of shafts. Can also be mounted perpendicular to shafts for thrust machining.

Options for shaft repair:

- We machine, sleeve and remachine to size

- We machine, customer welds and machines to size

Flange Facing + Drilling & Tapping

available with advance notice

CMM

LK Metrology

LK G80C Coordinate Measuring Machine. Travel distances: X: 2,500 mm (100 in), Y: 1,500 mm (60 in), Z: 1,000 mm (40 in). Powered by Polyworks software.

Milling - CNC

Toyoda

FV 1680 Vertical Machining Centre. 50 taper, 20 station tool changer with 63” x 31.5” x 31.5” travel. Rotary 4th axis.

Toyoda

Stealth 1365 Machining Center. 40 taper, 24 station tool changer with 63” x 31.5” x 31.5” of travel.

Matsura

Maxia MX520 5 axis Vertical Machining Center. 40 Taper, 60 station tool changer with 24.8″ x 22.04″ x 20.07″ of travel.

Horizontal Boring Mill

50 taper, Heidenhain TNC 410 CA controller. 4th axis 48″ table with 63.37” x 48.75” x 48” travel

Leadwell

1300 Vertical Machining Centre. 50 taper, 20 station tool changer with 52” x 30” x 30” travel.

OKK

VM5 II Vertical Machining Centre. 50 taper, 20 station tool changer with 40” x 20” x 20” travel.

Trak DPM

Power Drawbar, 30” x 17” x 18” Travel.

Trak FHM7

Power Drawbar, 60″ x 23″ x 20.5″ travel.

Milltronics

MB 20, Power Drawbar, 40” x 20” x 24” travel.

Milling - Manual

Fortworth Vertical Mill

50 taper, c/w 3-Axis Readout, with 60” x 24.25” x 25.75” travel

Dah-Lih Universal Mill

Acu-Rite III, 3 Axis with 38”x 14”x 17” power travel

First Knee mills

Heidenhain DRO up to 31”x 15.5”x 22” travel, 5” spindle

2 machines in total

Lathes - CNC

Mori Seiki

Model SL-400 BMC/2000 CNC Lathe, 25.5” swing x 81.2” between centres, 50 H.P. spindle motor, 18” chuck and 12 H.P. at the 12 station live tooling.

Nakamura- Tome

SC-250 CNC Lathe 8″ swing x 27″ between centres

Milltronics

ML 26 CNC lathe with 160” length, and 27” swing . 8 station turret.

SNK

SUT-12/2000 CNC Lathe, 6.5” swing x 33.2” between centres.

Lathes - Manual

TOS

Model SU 90 over the carriage, 46” maximum turning diameter, 264” between centers.

Stanko

Model 16K25-19.5” swing and 59” between centers.

Stanko

1I611P Lathe, with 10” swing and 24” between centers.

Grinding

Surface Grinders

All Tool has a total of 4 surface grinders.Our largest Chevalier Surface Grinder is equiped with a 11.75” x 23.5” chuck and has 26” x 13” x 14” travel with coolant and auto traverse

Heinman Tool & Cutter Grinder

In addition we have a diamond wheel tool and cutter grinder made by Heinman that is fitted with a compound rotary collet,

giving us the ability to create and manfuacture our on custom cutters when needed.

EDM

EDM Technology

a manufacturing process whereby a wanted shape of an object is obtained using electrical discharges (sparks). The material removal from the workpiece occurs by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. The collateral effect is that the material is broken down and carried away by the liquid.

Very tight tollerances and super finishes can be obtained by this process with adjustments to voltage / amperage and number of passes.

Wire EDM

This machine gives us exacting wire cutting abilities with full 4 axis ablities. This allows for precision features and complicated extrusion dies.(2 Machines total)

Part sizes up to 36″‘x24″19.9″

Sinker EDM

Die sinking EDM allows us to insert complex pockets and shapes into materials that may not be possible by any other method.

Part sizes up to 36″x24″x10″

Portable Machining

Line Boring and Hole Repair

- 1-1/4″ OD x 68″ long boring bar (machine faces from 1-1/2″ to 6″)

- 2-1/2″ OD x 96″ long boring bar (machine faces from 2-1/2″ to 18″)

With these two bars, holes from 1-1/2″ to 18″ can be bored. With some tool modifications holes smaller and larger (up to 24″) can be bored. Both bars are hydraulically driven (600 or 220 volt 3 diameter).

Bore repair is offered in 3 options:

- Bore and Bush

- Bore, customer welds and rebore to size

- With advanced notice of 36 to 48 hours we will bore, weld and bore to size

Blind Hole Boring and Repair

- 2-1/4″ OD bar

- hydraulic driven (600 or 220 vault 3 phase)

- Same 3 options of hole repair apply to this unit

- With advanced notice, this unit can be driven with 110 vault electric or pneumatic

Shaft Repair

- 18″ lathe bed with 12″ of automatic feed on “X” and 4″ of manual feed on “Y” axis.

- 36″ lathe bed wiqh 30″ of automatic feed on “X” and 4″ of manual feed on “Y” axis

Lathes can be mounted parallel to turning shafts. They are rotated by their own power or can be rotated by a portable means. Lathes can be placed anywhere along length of shafts. Can also be mounted perpendicular to shafts for thrust machining.

Options for shaft repair:

- We machine, sleeve and remachine to size

- We machine, customer welds and machines to size

Flange Facing + Drilling & Tapping

available with advance notice

CMM

LK Metrology

LK G80C Coordinate Measuring Machine. Travel distances: X: 2,500 mm (100 in), Y: 1,500 mm (60 in), Z: 1,000 mm (40 in). Powered by Polyworks software.